University Lecturer Martti Mäkinen and Laboratory Technician Tommi Itkonen from the Department of Physics and Mathematics came up with the new way of working.

“Studying physics is very theory-oriented. This is already the second time we replaced traditional lab work with the manufacturing of devices,” Mäkinen says.

“Last year, our students manufactured a spectrograph,” says Mäkinen who was in charge of the practical side of things.

“Our educational goal was to give students practical skills that they can later make use of. After all, physicists often need to build various measurement devices in the course of their work,” Mäkinen says.

“The glasses manufactured in this project could best be described as a combination of augmented reality glasses and a heads-up display.”

The idea was well received also by students taking the course.

“Manufacturing the glasses by ourselves took away some of the mythicism around them: these, too, are something that can be built, and no extraordinary skill is required,” Outi Kaltiainen says.

“Technology education gets frequently mentioned in teacher training, but the real link to technology can be missing entirely. This is why it was particularly interesting to manufacture these glasses,” Maria Aukee adds.

“This is also a nice change to theoretical learning, although I myself like it when things are approached through theory,” Raili Termälä points out.

“For me, this course was ideal, since I learn best by doing things,” Eeva Lana says.

Manufacturing involves multiple phases

The manufacturing of augmented reality glasses involves multiple phases, meaning that it was not possible to learn everything in the 30 hours allocated to the course.

“However, the students saw the entire manufacturing chain, i.e. what it takes to make a piece of equipment,” Mäkinen says.

“We let the students choose which type of glasses they would like to manufacture.”

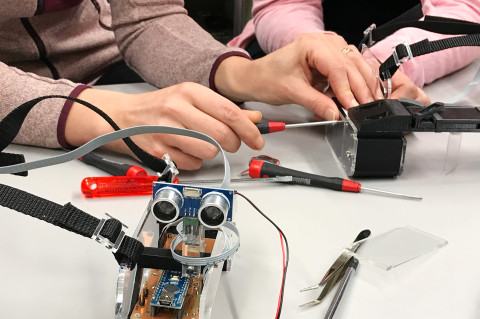

“I planned the electronics, or the circuit diagrams, and the students used those to create real component layouts, after which they soldered the circuit boards,” Itkonen explains.

A microprocessor was connected to a small display and to circuit board electronics, after which it was possible to program the processor. The other necessary plastic parts were cut with laser, and the lenses were 3D printed on campus.

“Our processing methods were so coarse that it wasn’t possible to adjust lens brightness yet,” Itkonen says.

“The processor controls a small display whose image, for example a measure of distance, is reflected into the eyes from glass plates. The brain interprets the images reflected into the left and right eye respectively as one image that appears to be hanging in the air for example one metre away. In reality, these glass plates are just a couple of centimetres away from the eye,” Mäkinen says.

Kaltiainen and Aukee manufactured glasses that use an ultrasound sensor to measure distance to target. Eeva Lana manufactured compass glasses that use a magnetic sensor, and Termälä glasses that measure temperature.

“These temperature-measuring glasses could be used in schools when teaching children about temperature differences. And I don’t see why these couldn’t be used when making chocolate or ice cream, for example,” Termälä says.

Future career can be found at the interface of disciplines

The autumn course also gave the students some food for thought. All of them have completed studies in another field before, or have decades of work experience, and finding employment in a new field is a question they have been thinking about.

“In my mind, the future looks more and more diverse,” Aukee says.

“As my studies have progressed, I’ve started to think about very new kinds of discipline combinations. For instance, physics and mathematics could well be combined with chemistry or biology.”

“I’m super interested in practically everything! It’s fascinating to find out how everything works,” Kaltiainen says.

“I haven’t given much thought to the future yet, but I am interested in the technological side of physics,” Lana says.

“Talking about the future makes me a bit nervous. I’m interested in working at the interface of physics and medicine,” Termälä notes.

“Last summer, we visited the neurosurgery clinic at Kuopio University Hospital and saw what kind of virtual glasses they were using. For instance, students of surgery could follow a procedure through 3D glasses, which was truly fascinating.”

- Virtual reality glasses are non-see-through glasses, and everything the person wearing them sees is artificial.

- Mixed or augmented reality glasses are transparent glasses that augment the reality with artificial objects.

- A heads-up display reflects an image on a see-through plate before the eyes. This technology is used in, e.g., fighter planes.